-

Phone:86-13606617661

-

WhatsApp:86-13606617661

Driving Precision & Efficiency: Our Production Floor Upgraded with Advanced Automated Injection Molding Systems

At Taizhou Huangyan Yuanli Plastic Products Factory, we understand that the quality of a finished Shaker Bottle or Space Cup is determined at the very beginning of the manufacturing process—the injection molding stage. To maintain our competitive edge and ensure superior product consistency, we have continuously invested in upgrading our core manufacturing infrastructure.

State-of-the-Art Machinery As captured in the recent photo of our production workshop, our facility is powered by a fleet of high-performance injection molding machines (including the advanced DIXIONG series). These machines are the backbone of our 16-unit equipment lineup. Unlike older models, these modern systems offer precise control over temperature and pressure, which is critical for molding leak-proof lids and durable bottle bodies with perfect clarity and strength.

The Power of Automation A key feature of our upgraded production line is the integration of Robotic Automation Arms (visible atop each machine). By automating the extraction of finished parts from the molds, we have achieved several key benefits:

Consistency: Robots do not get tired or make handling errors, ensuring every plastic part remains pristine and free from defects.

Speed: The automated cycle times are significantly faster, allowing us to increase our daily output to meet urgent wholesale orders.

Hygiene: Automated handling reduces human contact with the products immediately after molding, adhering to higher hygiene standards for our food-grade water bottles.

Commitment to Quality Materials Visible alongside our machines are bags of premium raw materials. We strictly use 100% food-grade, BPA-free materials (such as PP, PC, and Tritan) in these hoppers. The combination of high-quality raw materials and high-precision machinery ensures that Yuanli Plastics delivers products that are not only safe but also built to last.

Ready for Scale This modernized workshop represents our commitment to "Yuanli Power." Whether you need a small batch of custom designs or a container load of standard products, our automated production lines are ready to run 24/7 to meet your needs.

Global Reach: YURLEX Steals the Spotlight at the Internation

Global Reach: YURLEX Steals the Spotlight at the Internation

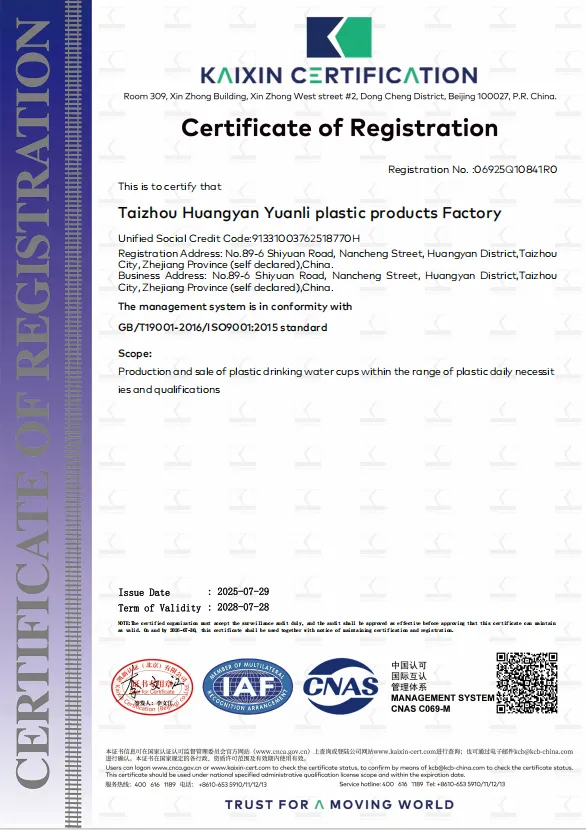

Quality First: Yuanli Plastics Successfully Renews ISO9001:2

Quality First: Yuanli Plastics Successfully Renews ISO9001:2

Logistics Optimization: Enhanced Warehousing Capability Ensu

Logistics Optimization: Enhanced Warehousing Capability Ensu

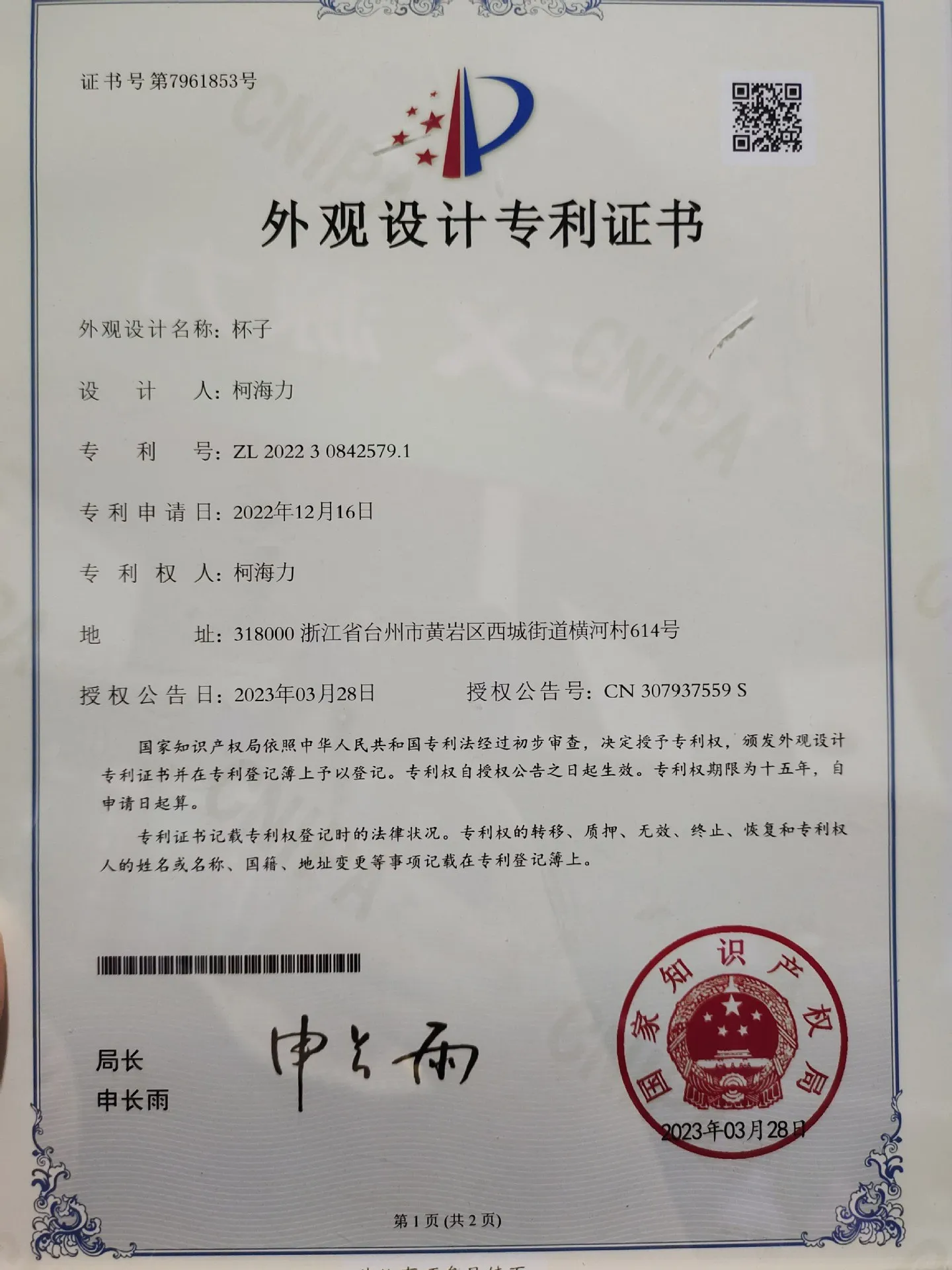

Innovation Recognized: Yuanli Plastics Awarded New Design Pa

Innovation Recognized: Yuanli Plastics Awarded New Design Pa